This section highlights a selection of custom-made products we have manufactured for clients around the world. From trailer parts such as brake drums and idler hubs to precision-machined components, each item represents our strong production capabilities, consistent quality assurance, and years of experience in high-volume OEM manufacturing.

Showcase examples

At Henan Broad Top Metalwork Ltd., we are one of the few factories in China capable of producing a wide range of custom metal parts at scale. Our production capabilities cover:

- High-volume manufacturing for OEM trailer components and industrial applications

- High-precision machining with zero tolerances

- Advanced materials such as Oxygen-Free Copper Parts

- Fully assembled shaft systems and axle components

- Oversized custom parts for heavy-duty machinery

Trusted OEM Supplier for Major U.S. Brands

We have proudly supplied custom-made trailer axle components to many of the leading trailer parts manufacturers in the United States. If you come across products stamped with TMW, they were manufactured by Henan Broad Top Metalwork Ltd.

Our production process strictly follows industry standards, ensuring high quality, competitive pricing, and on-time delivery at scale. We are your reliable partner for OEM trailer parts – from brake drums and idler hubs to complete axle assemblies.

Through our OEM service, you can customize high-performance components at the right price. Partner with us to streamline your supply chain with confidence and precision.

High-Capacity Custom Manufacturing

We specialize in large-volume custom manufacturing of metal parts, supporting clients with high demand across various industries. With our automated production lines and modern facilities, we are capable of delivering massive production volumes while maintaining strict quality control and cost efficiency.

Our scalable operations allow us to offer both high precision and competitive pricing — even for the most demanding OEM trailer parts and industrial components. When you need reliability at scale, Henan Broad Top Metalwork Ltd. is the partner you can count on.

Capability to Produce Complete Trailer Axles

Our production line has the full capability to manufacture complete trailer axle assemblies, including hubs, drums, spindles, and welded components. However, due to the high shipping costs associated with full axle systems, we typically focus on supplying individual components such as brake drums, idler hubs, and axle parts to ensure cost efficiency for our international customers.

For large-volume orders or customers seeking integrated supply solutions, we are fully equipped to provide complete mechanical systems tailored to your trailer manufacturing needs. Contact us to discuss how we can support your OEM or project-based requirements with a high-quality, scalable production strategy.

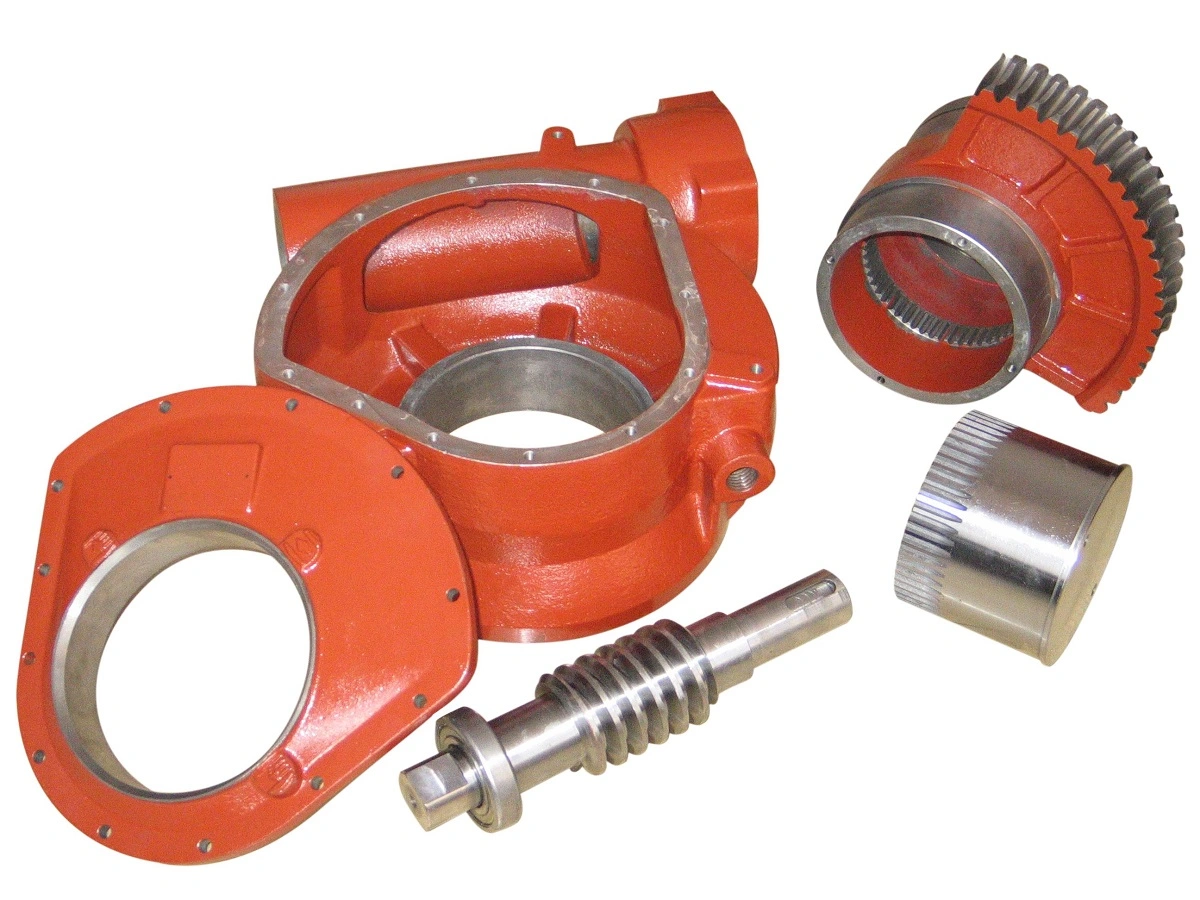

Zero-Defect Gearbox for French Nuclear Power Projects

This gearbox was manufactured for a nuclear power station in France, where zero-defect tolerance is strictly required. We have the engineering capability and manufacturing expertise to deliver such critical components that meet the highest standards of safety, durability, and precision.

Using advanced inspection methods such as X-ray testing, ultrasonic testing (UT), and magnetic particle inspection (MT), we ensure every internal and external feature is free of defects. Our process control system guarantees that all specifications comply with nuclear-grade manufacturing standards.

Custom 6,800 kg Pump Shell Successfully Delivered

This 6,800 kg pump shell was custom-manufactured by Henan Broad Top Metalwork Ltd. for one of our international clients. They chose us for our proven ability to handle large-scale, high-precision castings. The project was completed with excellent quality and on-time delivery.

The photo shows the client’s quality inspector on-site at our factory, verifying the pump shell before shipment. The successful completion of this project demonstrates our capabilities in heavy-duty component production and strict quality control for critical applications.

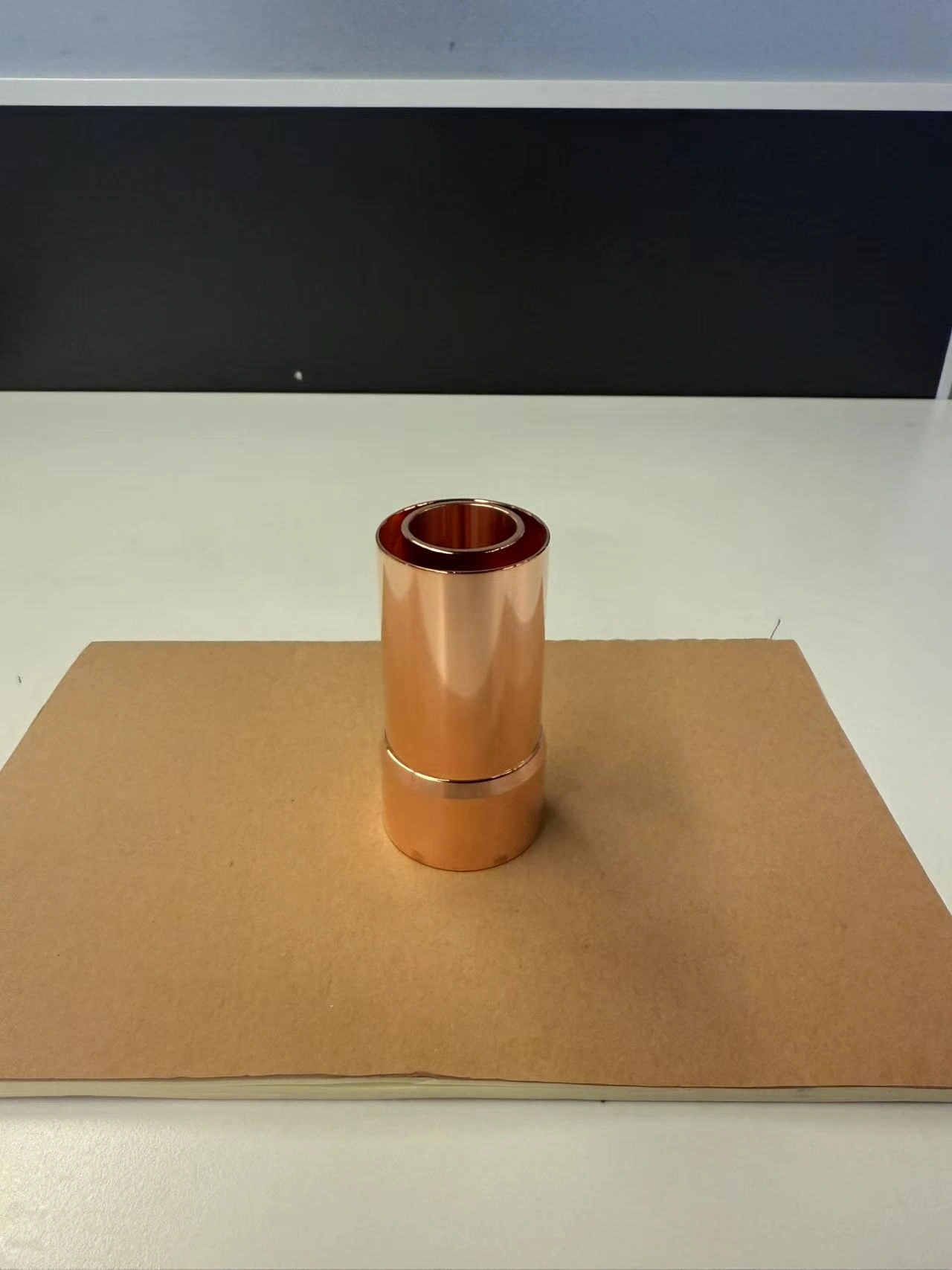

Oxygen-Free Copper Component for U.S. High-Voltage Power Applications

This component is specially manufactured for high-voltage power systems in the United States, using oxygen-free copper (OFC) with a strict oxygen content requirement of less than 0.05%. Our product exceeds expectations with an oxygen content of only 0.01%, ensuring exceptional conductivity and long-term reliability under demanding electrical conditions.

To date, we have delivered over 1,000,000 units of this copper component. Our client has repeatedly confirmed that we are the only supplier able to meet both their technical standards and target price in large volumes.

Our goal

We believe in delivering reliable, high-quality, and cost-effective custom parts through precision machining and long-term partnerships. Your design, our craftsmanship — built on trust, driven by quality.