Quality is at the heart of everything we do. At Top Metalwork, we believe that reliable quality reflects our confidence in our brand. It’s what sets us apart from other factories — offering competitive prices without compromising on precision or performance.

Brand origin

We use a range of advanced inspection instruments to ensure our parts meet high standards. Our founder, a top graduate in metal materials from China, named the company Top Metalwork to reflect our pursuit of excellence.

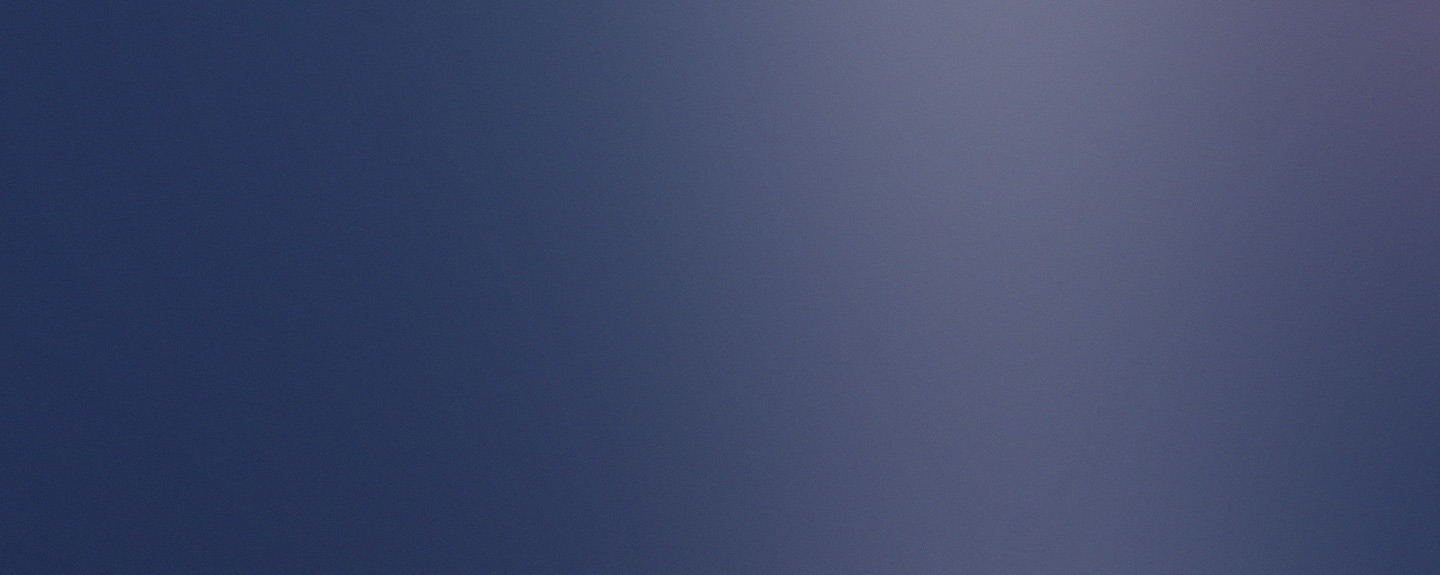

Metallographic Analysis

To ensure our castings meet performance requirements, we use metallographic microscopes to analyze the microstructure of brake drums and other components. Key indicators such as pearlite content are carefully examined to guarantee strength, wear resistance, and reliability.

Direct-reading Spectrograph

We use a direct-reading spectrograph to analyze the chemical composition of each heat of metal. This ensures that critical elements such as carbon, silicon, and manganese stay within required limits — providing stable performance and consistent quality for all our cast parts.

Brinell Hardness Tester

We use a Brinell hardness tester to measure the hardness of castings such as brake drums and hubs. This ensures that each part meets the required strength and durability standards, providing safe and long-lasting performance in real-world conditions.

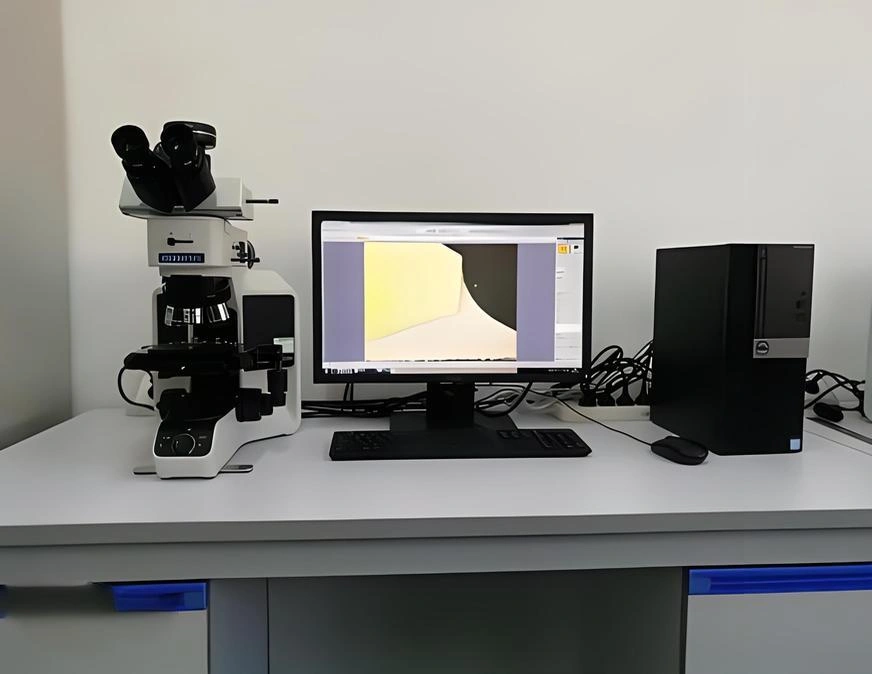

Coordinate Measuring Machine (CMM)

Our Coordinate Measuring Machine (CMM) performs precise dimensional inspections to ensure each part meets exact specifications. From critical mounting holes to complex geometries, CMM guarantees high accuracy and consistency across all our products.

Molten Metal Quick Analysis

Before casting, we perform quick analysis of molten metal to monitor key chemical elements in real time. This ensures that each heat meets the required composition standards, allowing us to control quality right from the source.

Solidification Process Simulation

We use solidification process simulation software to predict and optimize the flow and cooling of molten metal. This helps us prevent casting defects such as shrinkage or porosity, ensuring higher product integrity and improved material performance.

More Than Just Equipment

In addition to these tools, we have many other quality control systems in place to ensure every detail meets your expectations. We believe that talent is at the heart of production — our experienced engineering team, with over 20 years of dedication, is the true strength behind Top Metalwork.

We warmly welcome you to visit our factory. Let us show you the people and passion behind our quality.